Clip In Plain Tile

Clip-in false ceiling system with steel tile (600 mm x 600 mm) is manufactured out of 0. 50 mm thick regular modified polyester coated galvanized steel (z-120/180 gms total zinc coating mass of both sides, 240 mpa yield stress). These tiles can have square or beveled edges. It is available in matt finish on the exposed side and a primer coating on the back. Then the tile has 20-micron polyester coated finish and back coat of 5-micron alkyd primer. The rigid suspension system consists of rows of 0. 5 mm galvanized steel clip-in profiles installed at 600 mm c/c spacing to support the tiles. Suspension angles are suspended from the roof structure by gi ceiling brackets. They are joined to the clip-in profiles by hold-on clamps. The tiles / planks are held in place by pressure clips.

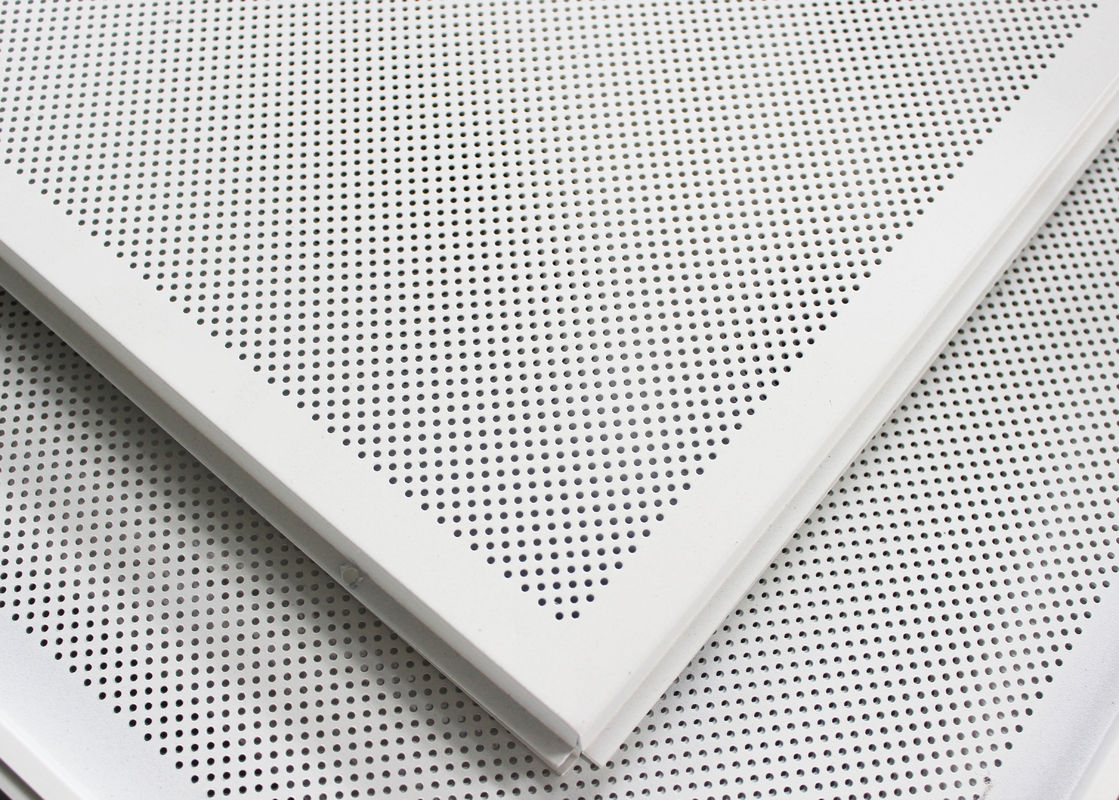

Clip In Perforated Tile

The tiles can be coil coated or powder coated in multiple colors. Perforation can be 2.5mm, 2.3mm or 1.8mm.

Application:

- These are suitable for food preparation areas and hospitals where cleanliness is important and tiles are frequently cleaned

and hosed down. - They are also used frequently in airport and transport hubs.

- Unlike mineral fibre boards, metal pan is impervious to moisture so they can be hosed down without damaging the board or causing it to sag or stain.

Features:

- Compact design

- Easy to install

- Accurate dimension

LAY-IN TILES

Lay-in false Ceiling System* with steel/aluminum tile 595 mm X 595 mm is manufactured out of 0.50 mm thick polyester coil coated galvanized steel 120/180 gms zinc coating or 0.7mm aluminum powder coated with 50 microns polyester paint in AA5050, AA3105 or AA1050 alum. Alloy. these tiles can have square or beveled edges . Coil coated steel tile has 20-micron polyester coated finish and back coat of 5-micron alkyd primer. The exposed metal grid comprises of Main Runners and Cross Tees, roll formed from galvanized steel of 120/180gsm zinc coating.

Lay in Perforated Tile

These tiles are available in 0.5mm thickness in coil coated and powder coated finish in size 595mm x 595mm with 2.5mm, 2.3mm and 1.8mm perforation.

Applications:

- Offices, places that require consistent maintenance, buildings with chilled beam systems such as the above NAB Docklands building by Woods bagot.

- Without perforations they are also generally more wind proof than other suspended ceiling systems.

Technical Characteristics / Properties of Metal Tile

| PROPERTIES | LAY-IN TILES | CLIP-IN TILES | |

| 1. | Metal | Steel / Aluminium | Steel / Aluminium |

| 2. | Surface | Plain / Perforated | Plain / Perforated |

| 3. | Coating | Coil / Powder-Coated | Coil / Powder-Coated |

| 4. | Size | 595x595mm | 600x600mm |

| 5. | Thickness | Steel(.5) & Aluminium(.7) | Steel(.5) & Aluminium(.7) |

| 6. | Colours | On - Demand | On - Demand |

| 7. | Zinc- Coating | Steel (120GSM) | Steel (120GSM) |

| 8. | Grid- System | Exposed- Grid- System | Concealed- Grid- System |